MB-MR-00510

Difference of printing

Laser Engraving / Pad Printing / Silk Screen Printing

Silk Screen Printing

1 color(s) artwork

On 1 position(s)

(20.00 cm X 6.00 cm)

Laser Engraving

1 color(s) artwork

On 1 position(s)

(20.00 cm X 6.00 cm)

Pad Printing

1 color(s) artwork

On 1 position(s)

(6.00 cm X 6.00 cm)

Pad Printing

2 color(s) artwork

On 1 position(s)

(6.00 cm X 6.00 cm)

Kraft paper box Without Logo

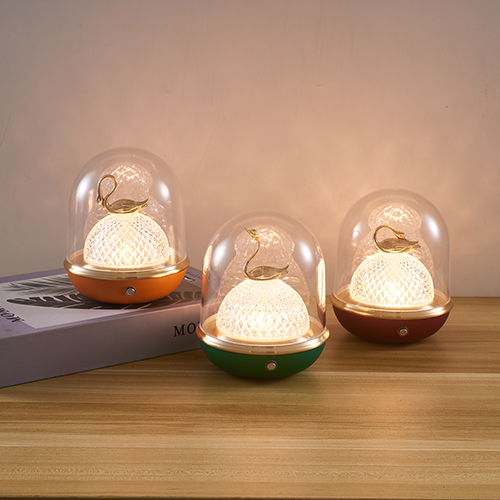

Related Showcases

Product Details

Make your campfire memories a little warmer with our modern take on Grandpa’s old camp cup. Thermo 3D™ double wall vacuum insulation means you won’t burn your hands (or scorch your tastebuds). It’s not possible to have too many of these, so stock up for both the office and base camp.

High quality 18/8 medical grade stainless steel is safe & strong and won't transfer flavor or leave a metallic aftertaste. All MiiR products are guaranteed to be 100% BPA free.

Size:8.50 x 8.50 x 9.98 (CM)

Weight:0.23KG

Material:stainless steel

Basic Packaging: Kraft paper box

Other Information:

Mass : 23.50 X 50.80 X 41.90 (CM)

Carton Box : 40 PCS / Carton Box

Inner Box : 1 QTY / Inner Box

Gross Weight : 9.80 KGS/Carton Box

Sign up Facebook

Sign up Facebook

Sign up Google

Sign up Google